Products

Metal Sheet Bending Machine

Metal Sheet Bending Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30 working days

Shipping Time : 40 days

Port : Tianjin

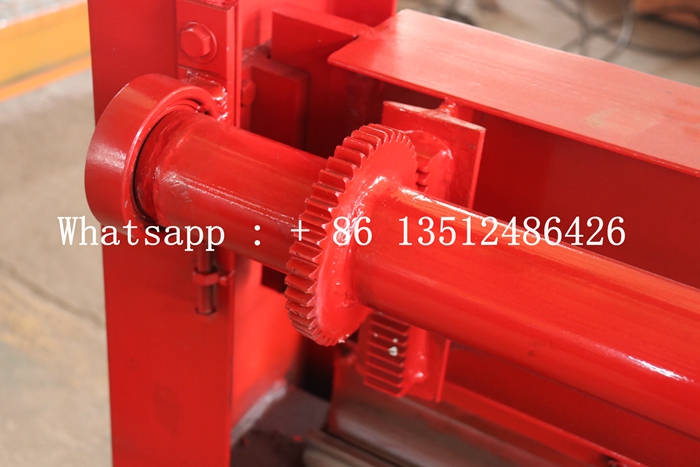

Metal Sheet Bending Machine

Specification

No. |

Number |

Metal Sheet Bending Machine |

| 1. | Raw material | Common hardness materials ≤1mm |

| 2. | Bending length | ≤4m |

| 3. | Pumping station electrical power | 3KW |

| 4 | Installation dimension | About 4600*800*2100mm |

| 5. | Weight | About 0.85 tons |

| 6. | Bending angle | The equipment incluye 3 mould 90° 120° 135° |

| 7. | Cylinder | 3 pcs oil cylinders of model 80 |

| 8. | Stroke | 150mm |

| 9. | Voltage | 380v 50hz 3p be customized |

Operation

1. Check each component of the hydraulic bending machine to ensure that all parts are in normal condition and are not loose or worn.

2. Place the metal workpiece to be bent on the workbench of the hydraulic bending machine and fix it with a clamp.

3. Adjust the height and angle of the workbench of the hydraulic bending machine to ensure that the position and angle of the workpiece and the mold match.

4. Turn on the power of the hydraulic bending machine, and then press the start button to start the hydraulic system.

5.Use the operating buttons on the hydraulic console to control the movement of the hydraulic cylinder and hydraulic jack so that they work according to the set bending angle and shape.

6. Observe the workpiece and mold during the bending process to ensure that the bending angle and shape meet the requirements

7. After completing the bending, turn off the power of the hydraulic bending machine and stop the operation of the hydraulic system.

8. Remove the bent workpiece from the hydraulic bending machine and perform subsequent processing or use.