Products

Roof Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Roof Double Layer Roll Forming Machine

Roof Double Layer Roll Forming Machine

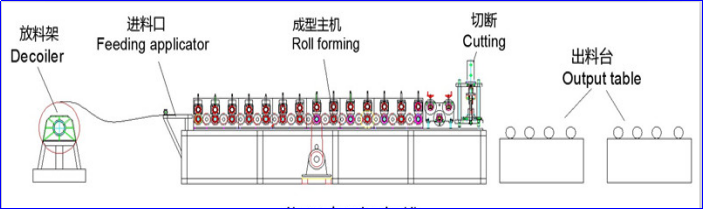

The Rroof double layer roll forming machine is a commonly used tile processing equipment. It is usually used to press materials such as color steel tiles and aluminum alloy tiles.

Roof Double Layer Roll Forming Machine

Specification

No. |

Number |

Roof Double Layer Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows |

18 13 |

| 19. | Size | 9000mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Operation

1. Preparation

a. Check whether all components of the double-layer tile press are intact, especially the electrical system and hydraulic system. b. Clean the work area, ensure that the operating environment is clean and tidy, and maintain good ventilation. Check the raw materials to ensure that their quality and specifications meet the requirements,

2. Adjust the parameters of the double-layer tile press

a. Select the appropriate rolling roller and mold as needed and install them on the double-layer tile press.

b. Adjust the rolling gap well to ensure that it rolls smoothly and is not too tight or too loose.

c. Check the hydraulic system of the double-layer tile press to confirm that it is working properly and has sufficient oil.

d. Check the electrical system of the double-layer tile press to ensure that all switches and buttons operate normally.

3. Start the double-layer tile press

a. Turn on the power switch of the double-layer tile press and press the start button to start the entire system.

b. Follow the instructions on the equipment operation panel and gradually adjust the working speed and pressure to achieve the ideal molding effect.

4. Feeding and forming

a. Place the pretreated raw materials on the feeding rack and adjust the position so that they accurately enter the rolling system. b. When the raw materials enter the rolling system, the double-layer tile press will automatically press and shape to form color steel tiles. Or aluminum alloy tiles. c. Check the quality of the finished product, and if there is any problem, adjust the parameters in time until the expected results are achieved.

5. Organize finished products

a. After the finished products are removed from the double-layer tile press, sort and stack them to avoid damage or deformation. b. Check the surface smoothness and flatness of the finished products. If there are any problems, make timely repairs and adjustments. c. Keep the work area clean. Remove remaining waste and debris and dispose of waste properly.

6. Close the double-layer tile press,

a. Stop the supply of raw materials and turn the task end indicator to off.

b. Turn off the hydraulic system and power switch, and disconnect the power supply.

c. Clean and maintain the double-layer tile press regularly to keep it in good working condition.