Products

Double Layer Roofing Sheet Roll Forming Machine

Double Layer Roofing Sheet Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Double Layer Roofing Sheet Roll Forming Machine

Double Layer Roofing Sheet Roll Forming Machine

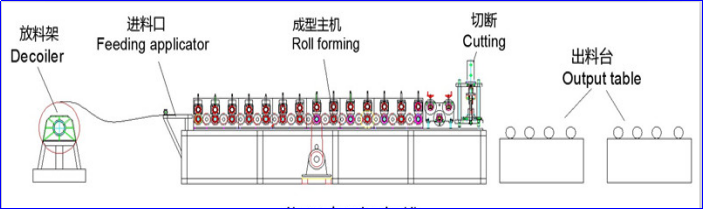

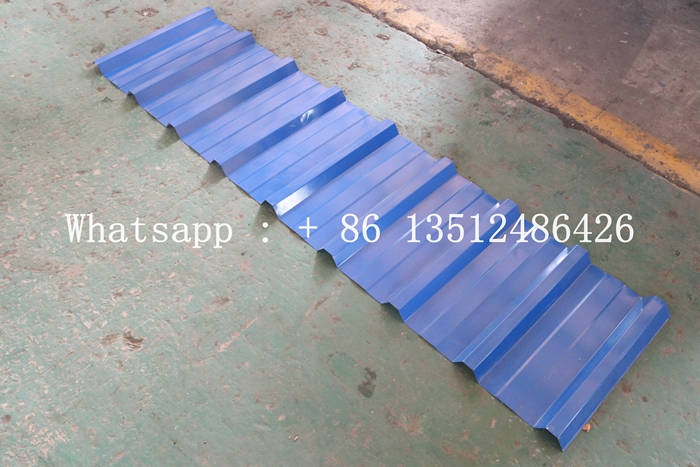

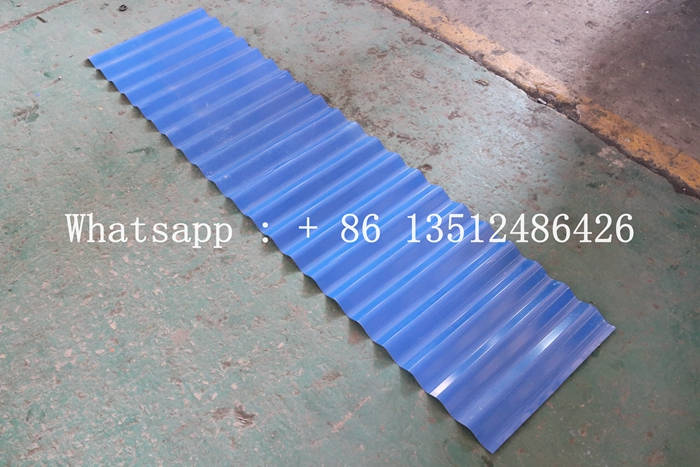

The double layer roofing sheet roll forming machine is composed of unloading, forming, and post-forming and cutting. The double layer roofing sheet roll forming machine produced have a smooth and beautiful appearance, uniform paint patterns, high strength, and durability. They are widely used in industrial and civil buildings, such as factories, warehouses, garages, and aircraft hangars. Rooms and walls of gymnasiums, exhibition halls, theaters, etc.

Its components include: complete machine, PC computer control system, hydraulic pump station system, and fully automatic post-shearing system

Equipment features: This double layer roofing sheet roll forming machine adopts high-level automatic control software to realize production information management. The entire unit automation control system adopts a highly integrated network to make the automation system perform better. The color steel tile equipment also has the advantages of easy operation, maintenance, maintenance, mechanical debugging, and mold replacement.

Double Layer Roofing Sheet Roll Forming Machine

Specification

No. |

Number |

Double Layer Roofing Sheet Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows |

13 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Maintain

1. Regular inspection: Regularly inspect the equipment, including the transmission system, hydraulic system, electrical system and other parts, to ensure the normal operation of each component.

2. Lubrication and maintenance: Regularly lubricate and maintain each lubrication point according to equipment requirements to maintain good lubrication status of the equipment.

3. Cleaning and maintenance: Clean and maintain the equipment regularly to keep the equipment tidy and clean to avoid dirt, rust and other problems.

4. Fastener inspection: Regularly check whether each fastener is loose. If it is loose, tighten it in time.

5. Replacement of wearing parts: Some wearing parts, such as rollers, bearings, etc., need to be replaced regularly to ensure the normal operation of the equipment.

6. Equipment maintenance plan: Develop a reasonable equipment maintenance plan and strictly follow the plan to ensure the normal operation and service life of the equipment.