Products

Trapezoidal Steel Roof Making Machine

Trapezoidal Steel Roof Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Steel Roof Making Machine

Trapezoidal Steel Roof Making Machine

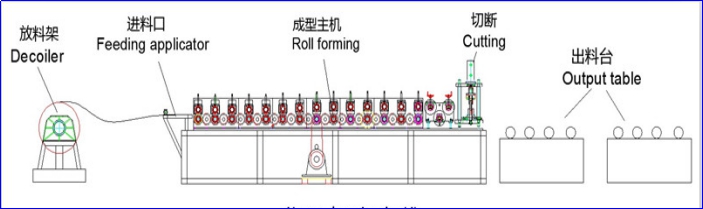

A trapezoidal steel roof making machine price is a forming equipment used to produce trapezoidal or tile-shaped metal sheets. It is usually fed from coils and undergoes a series of forming processes to finally obtain metal tiles or roof panels of the desired shape. Tile presses are suitable for construction, industrial equipment, transportation and other fields. Their products are widely used due to their lightweight, high strength and strong decorative properties.

It adopts the method of coil feeding and cold rolling forming, and is suitable for the manufacture of cold rolled sheets, galvanized sheets, aluminum sheets and other materials.

Trapezoidal Steel Roof Making Machine

Specification

No. |

Number |

Trapezoidal Steel Roof Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 20 |

| 19. | Size | 9500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. Efficient production capacity: Detailed introduction to the advantages of the trapezoidal steel roof making machine price in terms of production efficiency, such as production speed, output, etc.

2. Advanced control system: Introduce the control system of the trapezoidal steel roof making machine, including the degree of automation, programmable controller, etc.

3. High-quality materials and technology: Analyze the high-quality materials and advanced technology used in the trapezoidal steel roof making machine to improve the service life and performance of the machine.

4. Easy to operate and maintain: This illustrates the simplicity of operation and maintenance convenience of the trapezoidal steel roof making machine, which reduces the cost of use.