Products

Rolling Shutter Forming Machine

Rolling Shutter Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Rolling Shutter Forming Machine

Rolling Shutter Forming Machine

Rolling shutter forming machine are a new type of building material that are doors or windows made up of a number of horizontal rods (sometimes a strip or mesh system) hinged together. On doors, the action may be manipulable. It provides weatherproofing and protects the windows from vandalism and theft, has many advantages including ease of installation, short construction period, aesthetics, light weight yet high strength, rolling shutter doors have many uses including vans, garages, kitchens, schools, prisons and Warehouse door. In some parts of the world, blinds are subsidized by local governments due to inherent safety concerns. In areas that are frequently exposed to severe weather, rolling doors are used as a method of insulation to protect windows from hail damage.

1. Use advanced automatic control software to realize production information management.

2. It has the advantages of easy operation, maintenance, maintenance and mechanical debugging, and convenient mold replacement.

3. The automatic control system of the whole machine adopts a highly integrated network, which makes the performance of the automation system even more superior.

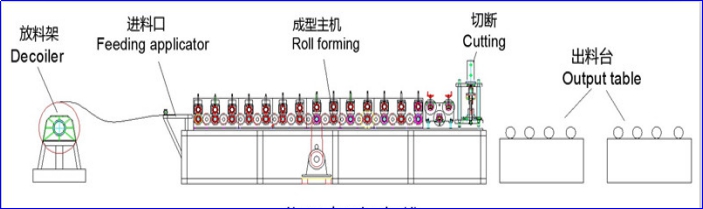

The production line includes uncoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system, and control system. The rolling shutter doors manufactured by this machine have neat appearance, uniform corrugation, high utilization rate and high strength.

Rolling Shutter Forming Machine

Specification

No. |

Number |

Rolling Shutter Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 18 |

| 19. | Size | 8000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |