Products

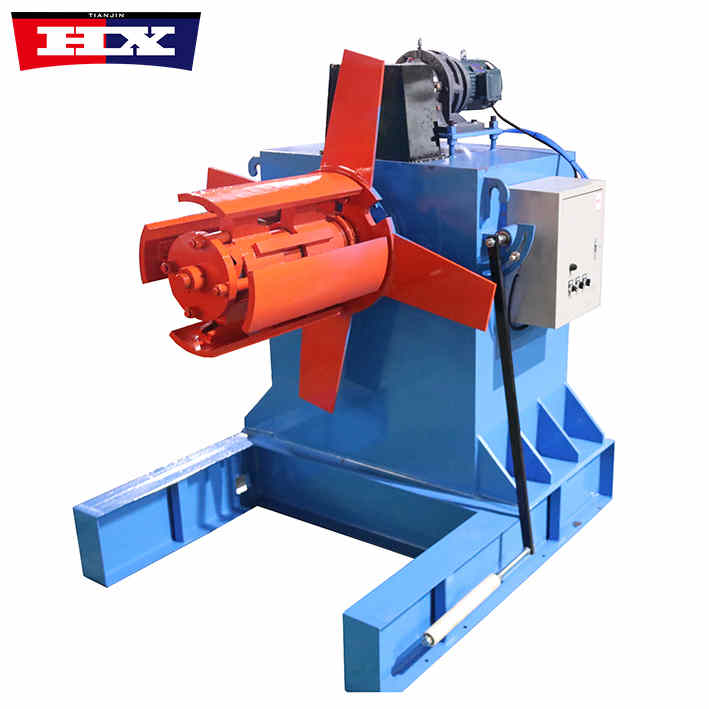

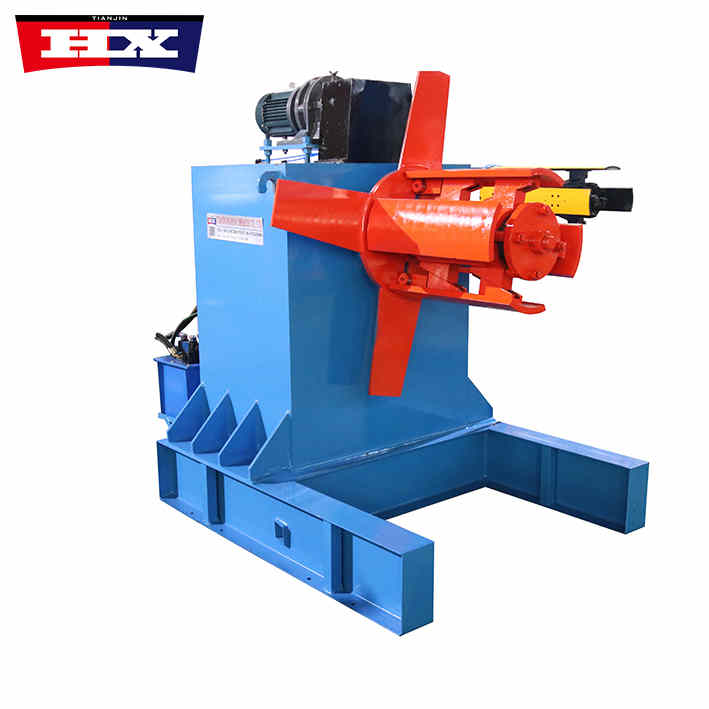

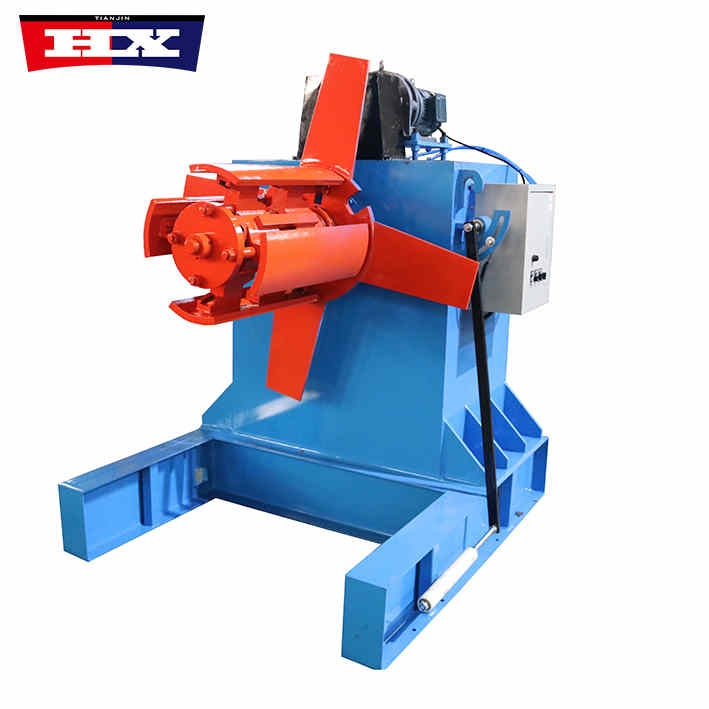

Decoiler Machine Steel

Decoiler Machine Steel

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Decoiler Machine Steel

Decoiler Machine Steel

1. The main shaft of the decoiler machine steel can rotate the coil material and cooperate with the flattening machine or slitting machine to transport the coil material.

2. The main shaft of the decoiler machine steel adopts the principle of hydraulic expansion and contraction, so that the inner hole of the coil material and the support arm are fixed and fixed.

3. The decoiler machine steel is equipped with a loading and unloading trolley and guide rails. Placing large-tonnage coils on the trolley can move forward, backward, and up and down, so that the coils can be stably and safely fixed on the main shaft of the decoiler.

The decoiler machine steel is a special equipment for leveling metal sheets. When designing the whole machine, the decoiler has a reasonable structure, compact shape, and high precision. The purpose is to ensure high strength, high precision, and high efficiency. The decoiler is used for leveling line steel plates and uneven plates. It can be composed of decoiling, leveling, shearing production lines and other plate product production lines according to relevant configurations.

Specification

No. |

Number |

Hydraulic Decoiler |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 5 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Advantages

1. High degree of automation: The decoiler machine steel is a fully automated equipment that can be started and stopped through contact control of the induction frame, which greatly improves production efficiency.

2. High unwinding accuracy: The decoiler machine steel adopts an electric control system, which can accurately control the tension and speed of the coil, ensuring the unwinding accuracy of the coil.

3. Easy to use: The decoiler machine steel has a simple structure and is easy to operate. You only need to put the coil material into the coil rack and turn on the power to automatically uncoil. No professional skills are required.

4. Wide range of applications: The decoiler machine steel can be used for unwinding many different types of coil materials, such as plastic film, paper, aluminum foil and other coil materials.

5. High safety: The decoiler machine steel adopts a variety of safety protection measures, such as safety shields, emergency stop buttons, etc., to ensure the safety of operators.