Products

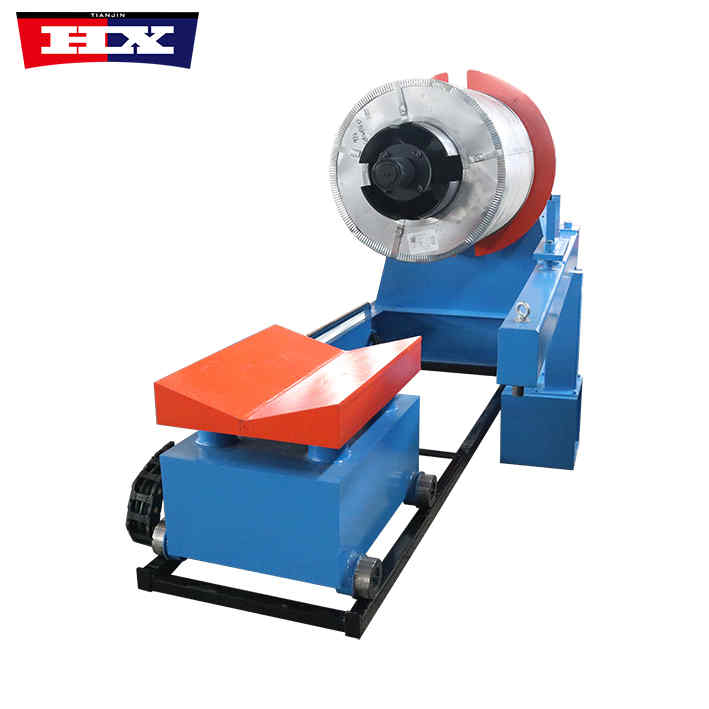

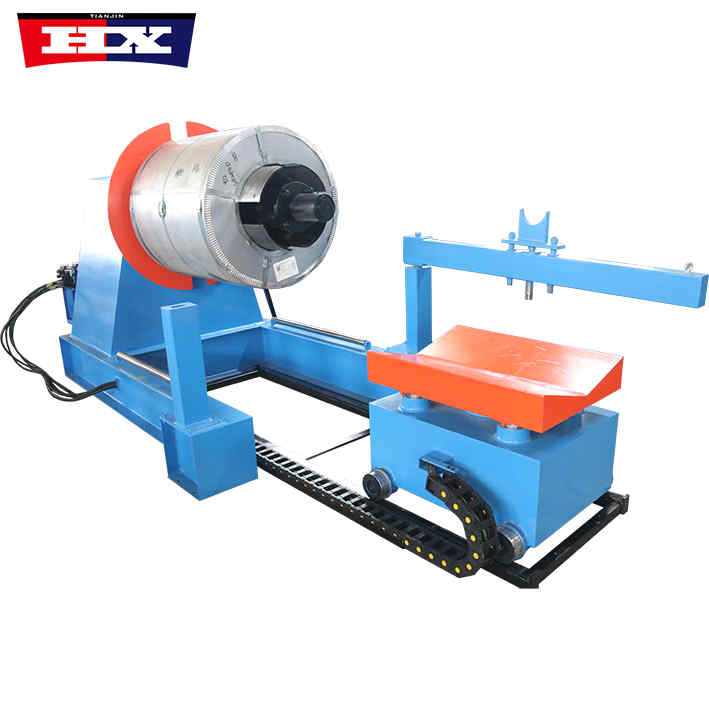

Coil Decoiler

Coil Decoiler

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Coil Decoiler

Coil Decoiler

The coil decoiler is mainly composed of coil support, material shaft, length-fixing device, feeding device, unloading device, drafting device, hydraulic control system and other components. Its working principle is to use the hydraulic system to push the bracket to move up and down, thereby controlling the unwinding and rewinding process of the raw material to achieve fixed-length cutting or winding.

After loading the raw materials into the roll support, tighten it through the material shaft, and then lift the roll support to the specified height through the hydraulic lifting device to align the roll with the feeding device. The uncoiler pulls the coiled material through the drafting device, and winds it smoothly on another reel through the unloading device. At the same time, the fixed-length device monitors the length of the coiled material in real time, and the coiling can be completed after cutting off the fixed length.

Specification

No. |

Number |

Coil Decoiler |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 7 tons |

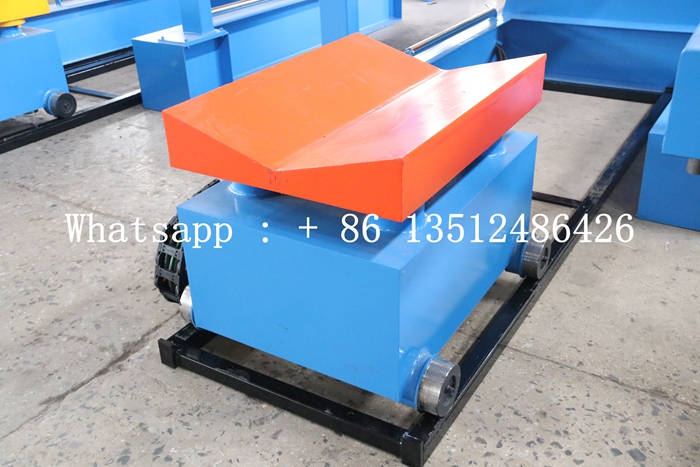

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Features

1. Precise and stable working performance: The hydraulic control system can monitor the length, width, weight and other parameters of the coil in real time, accurately control the rotation speed of the material shaft, ensure the accuracy and stability of coiling, and can meet the coil requirements of different industries. .

2. High production efficiency: The coil decoiler realizes automatic feeding and automatic unloading functions through advanced feeding devices and coiling devices, improving production efficiency and reducing labor costs.

3. Excellent safety performance: The hydraulic control system can realize safety monitoring and emergency shutdown functions, and can stop the machine operation in time when an abnormal event occurs, ensuring the safety of operators.

4. Flexible and diverse application scenarios: Coil decoiler are suitable for multiple industries, such as construction, textile, light industry, papermaking, etc., and have broad application prospects.